What is Cavitation?

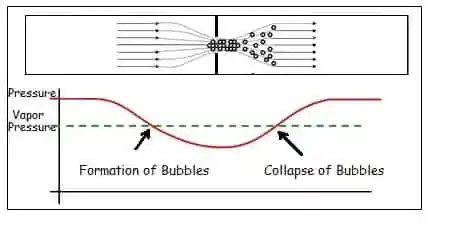

Cavitation is the process in which the liquid’s static pressure falls below its vapor pressure, resulting in the creation of small vapor-filled cavities in the liquid.

Two types of cavitation: Inertial and Non-Inertial.

Inertial Cavitation

It is a specific type that occurs when the fluid pressure fluctuates rapidly and drops significantly below the vapor pressure of the liquid. This causes the formation and subsequent violent collapse of small vapor bubbles within the fluid.

Here’s how it typically works:

Inertial cavitation begins with the formation of tiny vapor bubbles in a liquid. This happens when the local pressure drops below the vapor pressure of the liquid. Thus, allowing small pockets of vapor to form within the fluid. Once these vapor bubbles are formed, they are subject to the surrounding fluid’s dynamic pressure changes. If the pressure quickly rises again, the bubbles can collapse rapidly due to the surrounding pressure being higher than the vapor pressure inside the bubble.

The collapse of these bubbles is highly energetic and occurs extremely rapidly. During collapse, the bubble collapses asymmetrically. This collapse leads to the formation of a high-speed liquid jet or shock wave. Thus, generating very high temperatures and pressures locally (known as hot spots). The intense forces generated during the collapse of these bubbles can have significant effects. For instance, they can erode nearby solid surfaces, cause pitting or damage to metal components, and induce chemical reactions.

It is often intentionally induced and controlled in various applications. A few examples being, ultrasonic cleaning, ultrasonic homogenization, sonochemistry (using ultrasound to drive chemical reactions), and medical applications like ultrasound imaging and therapy. Control over inertial cavitation is crucial to harness its beneficial effects while minimizing potential damage to equipment or surrounding materials.

Non-Inertial cavitation

This type is known as the “stable cavitation”, and it involves the formation of small, stable vapor bubbles within a liquid. Unlike its inertial counterpart, where bubbles collapse violently and rapidly, non-inertial cavitation bubbles remain stable for a longer duration. However, it can still induce effects such as microstreaming, localized heating, and mechanical agitation of the surrounding fluid.

These effects can be harnessed in various applications such as ultrasonic cleaning. Ultrasonic cleaning is the gentle agitation and microstreaming around stable bubbles help in removing contaminants from surfaces.

Where does It Occur?

Cavitation is a significant consideration in engineering and fluid system designs to avoid equipment damage and inefficiencies. It most often occurs in pumps, propellers, hydraulic systems, turbines, internal combustion engines, and valves.

Why Avoid Cavitation?

Avoiding cavitation is important because it can lead to damaged equipment, loss of efficiency, noise and vibration, performance degradation, and safety concerns.