What is a Valve?

Before diving into valve sizing an understanding of what valves are is needed. A valve is a mechanical device that controls the flow of a liquid, gas, or slurry through a systematic passageway such as pipes. A valve achieves control by stopping, varying, or starting the fluid flow, controlling the direction of the flow, regulating process pressure, and relieving over pressure. For example, think of a valve like a faucet in your kitchen or bathroom sink: by turning the handle you control and flow of the water. For more knowledge on what a valve is, the different types of valves, and the industries they serve; click here.

What is Needed to Size a Valve?

Valve sizing is done by calculating the valve’s flow coefficient (Cv). The flow coefficient is a key parameter that expresses the valve’s flow capacity. In order to calculate the flow coefficient requires knowledge of the process data, understanding the flow characteristics, and knowing the correct valve type for the application.

Gathering Process Data

Gathering process data is the first step towards sizing a valve properly. Specifically, flow rates, inlet/outlet pressure, fluid type, temperature, and line size are needed.

- Flow Rates: Typically given in GPM (Gallons Per Minutes) or LPM (Liters Per Minute).

- Inlet Pressure/Outlet Pressure: Inlet pressure is the upstream pressure from the valve and the outlet is the downstream pressure from the valve.

- Fluid Type: Fluid type is the properties of the fluid that will be flowing through the pipe. For example, fluid density, viscosity, and vapor pressure are all properties of the fluid.

- Temperature: Temperature must be known to help determine the fluid’s property characteristic at certain temperatures and the expansion effects that will occur. For example, fluids at higher temperatures become less viscous.

- Line Size and Pipe Schedule: Knowing the line size helps ensure proper connection between the pipe and the valve. Furthermore, the valve does not need to be the same size as the pipe.

- Flow Characteristics: Three flow characteristics exist flow: Linear, equal percentage, and quick opening.

Flow Coefficient

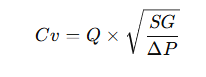

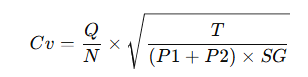

After gathering all of the process data the flow coefficient can be calculated. Furthermore, there are two calculations to determine the flow coefficient based on whether the fluid is a gas or liquid.

Liquid Flow (Non-Compressible Fluids)

where:

- Q = Flow Rate (GPM)

- SG = Specific Gravity (relative to water at 60F)

- ∆P = P1 – P2 (inlet pressure at maximum flow – outlet pressure at maximum flow)

Gas Flow (Compressible Fluids)

where:

- N = Gas Constant (based on units)

- T = Temperature

- SG = Specific Gravity (relative to air)

Correct Valve Type

Knowing the correct type of valve that is best suited for the application is of utmost importance. As a demonstration, let’s take a look at an application that requires a valve that offers precise fluid flow control. A globe valve is best suited for the application over a gate valve. The reasoning is that a gate valve operates by being either fully open or fully closed and globe valve operates by being partially open. Thus, a globe valve can offer more control than just being opened or closed. For further distinction and information on which valves are best for which applications click this link.