What are Cooling Towers?

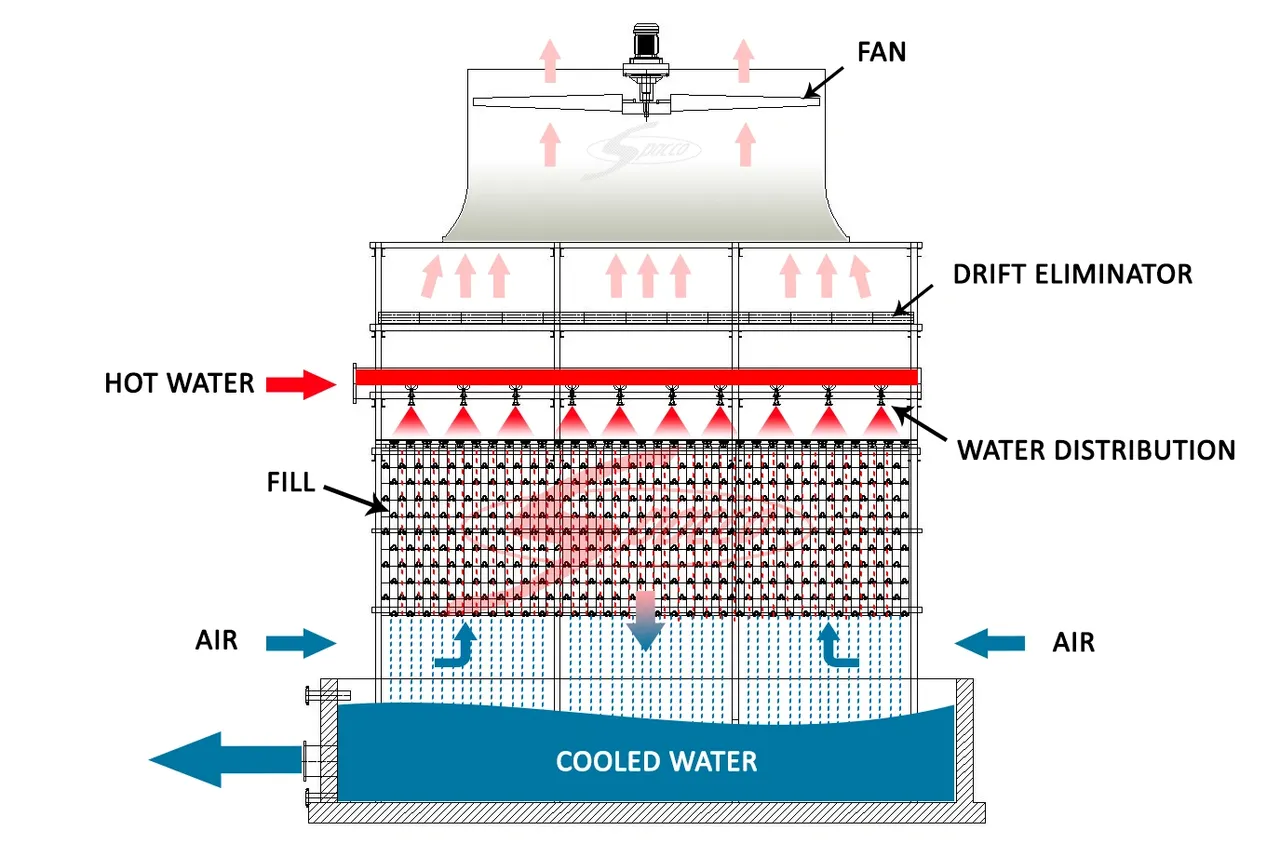

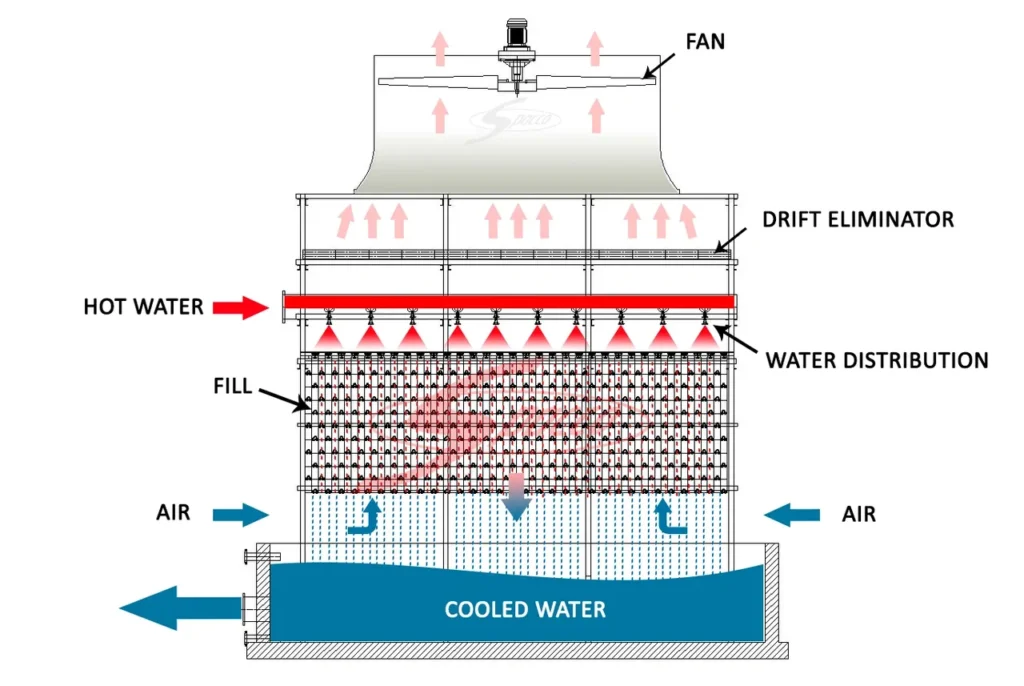

Industrial chilling and cooling towers are a critical component of many refrigeration systems. More precisely they can be found in power plants, chemical processing, steel mills, and across many other manufacturing companies where process cooling is necessary. In many instances a cooling tower is used as a huge heat exchanger. Additionally, the most common components in a cooling tower system are fans, collection basins, supply pipes, and fill media. Spray nozzles and drift eliminators can be added to improve cooling efficiency and reduce the amount of water lost during evaporation.

Different Classifications

- Natural Draft

- They rely on natural convection to circulate air throughout the tower, which then cools the water. The air movement occurs due to differences in density between the entering air and the internal air within the tower. Warm, moist air, which is denser than cool air, will rise through the tower. As a result of the warm air rising the cool air from outside will fall creating a constant cycle of flow. These towers are most commonly used in large power plants and industries with access to seemingly infinite cooling water flow.

- Mechanical Draft

- Mechanical draft cooling towers can be found in power generation, chemical processing, petrochemical refining, manufacturing, and HVAC systems. Air is forced through the structure by a fan that circulates air through the tower. Common fans used in these towers include propeller fans and centrifugal fans. While mechanical draft towers are more effective than natural draft towers, they consume more power and cost more to operate as a result.

Airflows of Mechanical Cooling Towers

- Crossflow

- The water flows downward through the fill while the air flows horizontally, across the flow of the falling water. However, a crossflow cooling tower’s fans and motor drive require weather proofing against moisture which can lead to freezing making it less efficient.

- Counterflow

- The air flows upward, counter to the flow of the falling hot water. Allows maximum performance out of each area and helps minimize the pump head requirements. Counterflow cooling towers are less likely to ice up in cold weather conditions and can save energy in the long run.

Heat Transfer Methods

- Wet Cooling Towers

- They are cost-effective and will achieve the most possible cooling. They are measured by decreasing the process temperature and the wet bulb temperature, and how cold the water temperature becomes.

- Dry Cooling Towers

- They work by using an electric motor which separates the working fluid from the ambient air to transfer heat (these towers use no water).

- Fluid Coil Cooling Towers

- These towers are a closed-circuit system, water is mixed with glycol to form a fluid that then moves through a coil that is exposed to air afterward. These require more horsepower, but they offer high productivity and low downtime.

Cooling Tower – Associated Equipment

Equipment that is associated with cooling towers that ensure that they run efficiently and effectively are electric heat trace and electromagnetic flowmeters. Heat trace cable is used for freeze protection on supply, return, balance, make up, and drain water lines. Mag meters are installed help regulate flow, pressure, and are used for monitoring temperature.