What is Water Hammer and What Causes It?

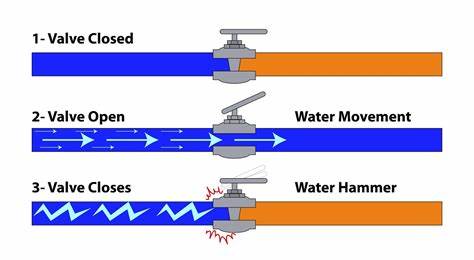

Water hammer is a phenomenon that occurs in plumbing and piping systems when the flow of water is suddenly stopped or changed, causing a shockwave to travel through the pipes. The sudden change in pressure results from the abrupt stopping of water moving at high speed, creating a loud banging or thumping noise.

It typically happens when a valve is quickly closed, causing the moving water to collide with the closed valve and creating a pressure surge. The shockwave can cause vibrations in the pipes, which is where the “hammering” sound comes from.

How to Avoid Water Hammer

Preventing water hammer requires a combination of design considerations, equipment, and maintenance practices. There are several effective ways to reduce or eliminate water hammer:

1. Install Water Hammer Arrestors

- Arrestors absorb the shockwave caused by sudden water stoppages. Thus, reducing the pressure spike. They can be installed at strategic points in the system, such as near valves and quick-closing equipment.

2. Slow Valve Closure

- Use valves that close slowly or are equipped with controls that prevent rapid closure. Therefore, preventing the sudden stoppage of the water flow.

3. Pressure Relief Valves

- Install pressure-relief valves to help manage any pressure surges by venting excess pressure from the system. For example, installing the valves at key points where surges are most likely to occur will reduce or prevent the pressure surge.

4. Increase Pipe Size

- By increasing the pipe size, it allows more water to flow smoothly. Thus, reducing the likelihood pressure spikes cause by rapid flow changes.

5. Use Flexible Hoses or Expansion Joints

- Flexible hoses or expansion joints can absorb some of the shock waves and vibrations cause by sudden changes in pressure. Therefore, these components can help prevent damage to rigid pipe sections.

6. Install Surge Tanks or Air Chambers

- By installing surge tanks space can be provided for water to temporarily “move” when pressure surges occur. The air in these chambers compresses and absorbs the shock, thus reducing the impact of the hammer effect.

7. Proper System Design

- Ensure that the system is designed with appropriate flow rates, pipe sizing, and valve placement to avoid high velocities or abrupt changes in flow.